Logistics and Solutions

Complete logistics for air, ground and sea transportation worldwide, including door-to-door service.

OxEnergy provides

Complete logistics for air, ground and sea transportation worldwide, including door-to-door service, mobile cranes, special loads, and insurance coverage; all under the highest safety practices.

We also take care of the logistics involved in moving assets from one country to another and back, so your company can have peace of mind with the entire related customs, import, and export process. In addition, Costa Rica's Active Improvement Regulation allows the entry of Machines and their associated components into the Costa Rican customs territory exempt from all taxes, which translates into significant savings for your company.

Contact our Logistics Department for more information about this duty-free door-to-door service

Online Monitoring and Predictive Damage Prevention

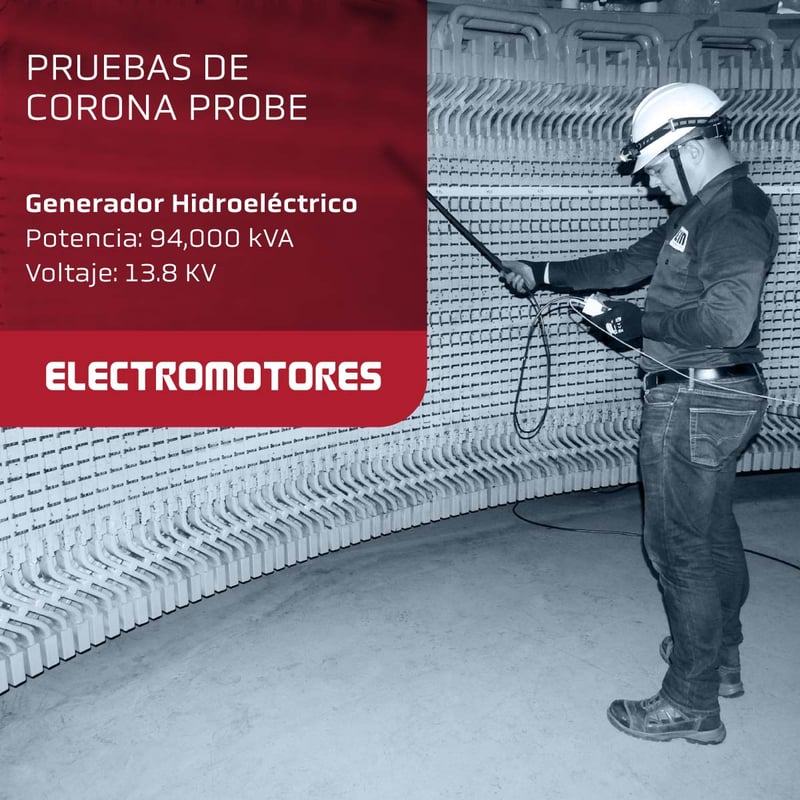

We supply the latest Online Condition Monitoring technology to carry out static and dynamic electrical tests, vibration analysis, alignment tests, thermography, and non-destructive tests on site.

%2012.24.43%20a.m..png?width=1000&height=656&name=Captura%20de%20pantalla%202023-12-12%20a%20la(s)%2012.24.43%20a.m..png)

Features

A Single Trusted Provider

Our on-site projects include diagnostics, testing, acquisition of required components, maintenance and repair of equipment, as well as insurance, transportation and final delivery of assets. This saves time and resources by having a single supplier handling the entire supply chain. We offer comprehensive logistics services, covering all stages of the process.

Import, Export, and Regulatory Management

We take care of the logistics required to move assets from one country to another. With our customs, import and export services, your company can have peace of mind with the entire related process.

All units arriving at our workshop benefit from Costa Rica's Special Entry Regime, which allows assets to enter the customs territory exempt from all taxes and are delivered under warranty.

Anticipating Problems and Providings Solutions

We offer significant cost savings by diagnosing failures, scheduling required maintenance and avoiding major and costly breakdowns. Our commitment is to provide reliable and efficient service, ensuring that your equipment only stops when you want it to.

-

Level 1 Service Package

Routine Testing and Inspection

-

Level 2 Service Package

Routine Testing and Inspection

-

Level 3 Service Package

Major Maintenance

Recommended Testing

STATIC ELECTRICAL TEST

- Resistance measurement per circuit and per phase

- Medition of insulation resistance to ground

- Polarization and dielectric absorption index

- Surge

- Hi-Pot

OTHER TEST

- Vibrations

- Alignment

- Thermography

- Dynamic Electrical Testing

Recommended Services

Visual inspections

Recommended Testing

ELECTRICAL DIAGNOSTIC TESTS

- Measurement of resistance per circuit and per phase

Measurement of insulation resistance to ground, polarization index and dielectric absorption

Surge @ Rated Voltage

STATIC ELECTRICAL CERTIFICATION TESTS

- Measurement of resistance per circuit and per phase

Measurement of insulation resistance to ground, polarization index and dielectric absorption

Hi-Pot Testing (Certification test)

Surge Testing (Certification test)

FINAL DYNAMIC TESTS

- Measurement of Currents, Speed, Temperatures

Vibration Measurement and Analysis in Workshop (Mechanical Certification) @ Rated Speed

Recommended Services

DISASSEMBLY AND INSPECTION

- Verification of bearing fits

Bearing housing adjustment check

Checking of trunnion fits

Verification of shaft eccentricity

SQUIRREL CAGE ROTOR TESTS

- Verification of shaft eccentricity

Integrity test on squirrel cage rods

Trunnion adjustment check

Rotor dynamic balancing

WINDING INSPECTION

- Inspection of winding connections, winding heads and support rings

Condition inspection and adjustment of shims

Check for contamination, discoloration, insulation condition, mechanical looseness, movement, and wear

Inspection of power cable terminals fastening

Verification of operation of RTDʼs sensors and heating resistors

General check of junction box condition

General inspection of insulation

Visual inspection of the stator core

WINDING CLEANING

- Winding cleaning by washing with steam and hot water to remove all the dirt

Cleaning of the core using dry compressed air, non-metallic abrasive brushes

Minor corrections in the insulation system (those considered as preventive maintenance work)

DRYING PROCESS

VARNISH MAINTENANCE PROCESS

ASSEMBLY PROCESS

- Bearing installation according to original design (Induction mounting method)

Reinsertion of rotor into stator

Installation of removed accessories

Assembly and application of anticorrosive paint

Recommended Testing

ELECTRICAL DIAGNOSTIC TESTS

- Measurement of resistance per circuit and per phase

Measurement of insulation resistance to ground, polarization index and dielectric absorption

Surge

STATOR CORE TEST

- Stator core sizing

Testing and verification of stator core condition

Calculation of losses (Watts/kg) and hot spot verification

Thermography

STATIC ELECTRICAL CERTIFICATION TESTS

- Measurement of resistance per circuit and per phase

Measurement of insulation resistance to ground

Polarization index and dielectric absorption

Hi-Pot (Certification test)

Surge (Certification test)

FINAL DYNAMIC TESTS

- Measurement of Currents, Speed, Temperatures

Vibration Measurement and Analysis in Workshop (Mechanical Certification) @ Rated Speed

Recommended Services

DISASSEMBLY AND INSPECTION

- Verification of bearing fits

Bearing housing adjustment check

Checking of trunnion fits

Verification of shaft eccentricity.

SQUIRREL CAGE ROTOR TESTS

- Verification of shaft eccentricity.

Integrity test on squirrel cage rods

Trunnion adjustment check

Rotor dynamic balancing

REMOVAL OF EXISTING WINDING

- Removal of shims / winding.

Data collection of the different winding dimensions, physical location of winding groups, connections, according to original layout.

General core cleaning.

COIL INSTALLATION | INVERTER DUTY INSULATION SYSTEM

- Inverter Duty type insulation system.

Revision of winding design using original data base and/or calculation program.

Rewinding with class H insulation (180 °C).

Installation of special INVERTER DUTY wire for VFD applications.

WINDING CONNECTION

- Connection according to original design.

Soldering of joints/insulation with special tapes for the application (silicone tape, mica, fiberglass and spaghetti).

VARNISHING PROCESS (DIP&BAKE - VPI)

ASSEMBLY PROCESS

- Bearing installation according to original design. Induction mounting method.

Reinsertion of rotor into stator.

Installation of removed accessories

Assembly and application of anticorrosive paint - FINAL REPORT

Success stories

-

Panamá

Thanks to the favorable Active Improvement Regulations that we qualify under at OX ENERGY, we transported and delivered a 5000 HP/ 10 ton engine to Petroterminal Panama after major maintenance in our Service Center, with significant savings.

-

República Dominicana

Preventive maintenance on a 14MVA Hitachi turbogenerator in a sugar mill. During the initial insulation tests, a high current leakage was detected, resulting in a low insulation value (120 Ω) specifically in Phase 1.

With the inspection work, it was possible to observe crystallized and thermally degraded insulation in the area of the power outputs.The next stage of this project involves replacing the insulation and performing timely maintenance of the machine. -

El Salvador

Successful shipment of a container with tools and equipment needed for major maintenance of L4 in El Salvador, taking advantage of the ferry that connects both countries.

We also picked up a 20 MW/ 62 ton INE El Salvador generator taking advantage of the ferry service in that country to bring it to our facilities and perform a major maintenance procedure and rotor rewind. The assets that we transport for repair in our workshop in Costa Rica are tax exempt when entering the country and, with our complete logistic system, we take care of all the related process.

The entire OX ENERGY Staff is at your disposal!

Let's meet to talk.

We offer a personalized approach to our clients, including site visits and complimentary meetings to fully understand your requirements, so that we can provide accurate proposals optimized for both time and cost.

Contact us!

OXenergy | Products and Sevices for Heavy Industry and Power Generation.

We will be glad to answer your questions. Please share with us the specific details of your request so we can best support you.